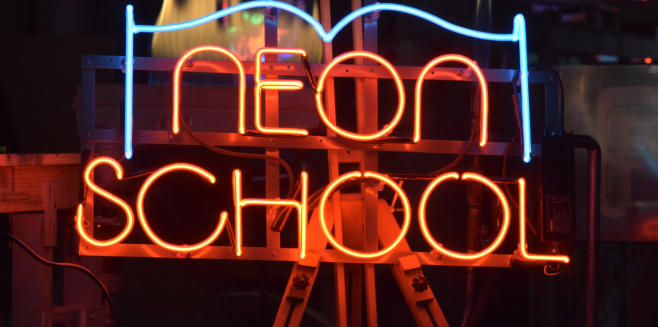

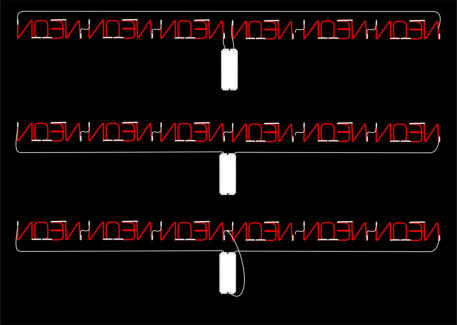

Centre Tap loop

Long loop

Earth Return loop

Centre tap loop transformer GTO/HT leads are at the

centre of the number of sections bridging is linked from

the inside to out on both sides at the ends a long link is

used to complete the loop if a metal substrate is used the

metal must be earthed to the transformer

Centre tap earth return the transformer GTO/HT leads are at the centre of

the number of sections bridging is linked from the inside to out on both

sides at the ends a long bridge is used to complete the circuit by connecting

both to the earth point of the transformer it is required to label all of the

metal surface connections with the correct warning labels. This method

can also be used to wire to seperate signs as long as the footage is rated

to each side of the transformer.

Centre tap Earth return the transformer GTO/HT leads are at the centre of the

number of sections bridging is linked from the inside to out on both sides at

the ends the neon are connected to the earth point of the transformer, when

on a metal surface there must also be an earth link from the transformer to the

metal surface it is required to label all of the return connections with the correct

warning labels

Centre tap earthed return

Centre tap earth return

Centre tap earthed bonded

Centre tap earth bonded return the transformer GTO/HT leads are at the

centre of the number of sections bridging is linked from the inside to out

on both sides at the ends the neon can be connected to the metal substrate

then a bonding cable from the substrate to the earth link of the transformer

it is required to label all of the return connections with the correct warning

labels this method is normally kept to large sky signs that need lifting

equipment to access

Long loop transformer GTO/HT leads are at the end of the

number of sections bridging is linked from section to

complete the loop, an earth return will seperate both sides

of the transformer but it is also inefficient way for loading

a transformer if a metal substrate is used the metal must be

earthed to the transformer

Long loop transformer GTO/HT leads are at the end of the

number of sections bridging is linked from each section to

complete the loop. Below’s wiring scheme is basically the

easiest to use, but it is the most inefficient way for loading

a transformer. if a metal substrate is used the metal must be

earthed to the transformer

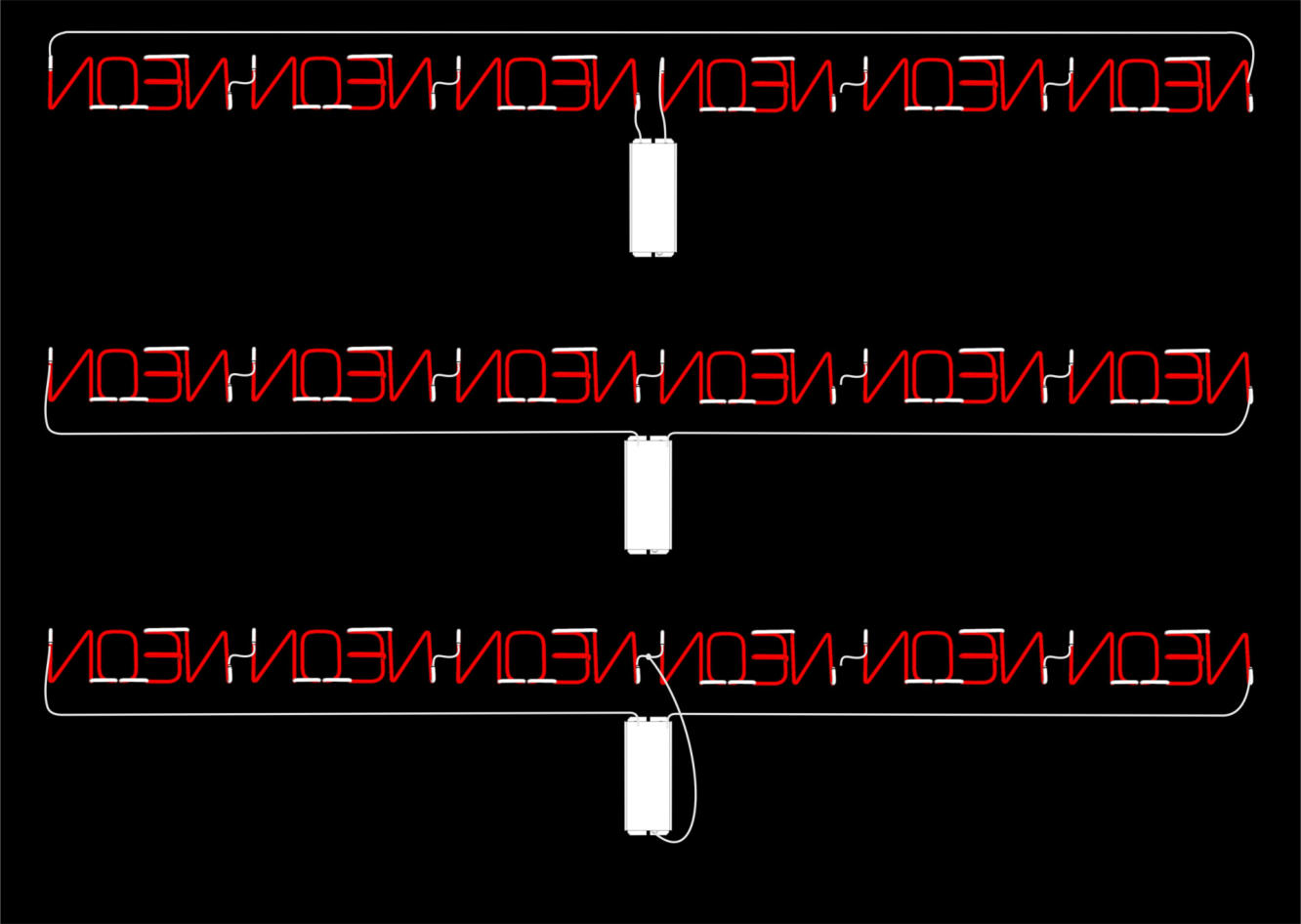

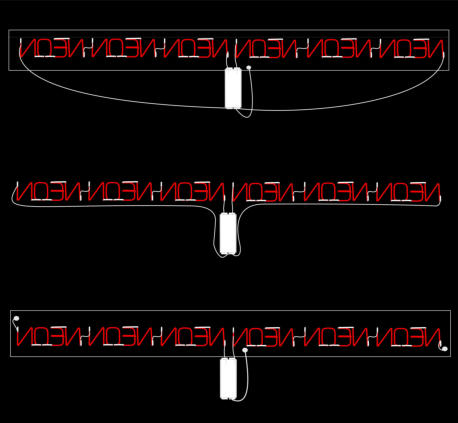

Centre Tap loop

Long loop

Earth Return loop

Centre tap loop transformer GTO/HT leads are at the

centre of the number of sections bridging is linked from

the inside to out on both sides at the ends a long link is

used to complete the loop if a metal substrate is used the

metal must be earthed to the transformer

Centre tap earth return the transformer GTO/HT leads are at the centre of

the number of sections bridging is linked from the inside to out on both

sides at the ends a long bridge is used to complete the circuit by connecting

both to the earth point of the transformer it is required to label all of the

metal surface connections with the correct warning labels. This method

can also be used to wire to seperate signs as long as the footage is rated

to each side of the transformer.

Centre tap Earth return the transformer GTO/HT leads are at the centre of the

number of sections bridging is linked from the inside to out on both sides at

the ends the neon are connected to the earth point of the transformer, when

on a metal surface there must also be an earth link from the transformer to the

metal surface it is required to label all of the return connections with the correct

warning labels

Centre tap earthed return

Centre tap earth return

Centre tap earthed bonded

Centre tap earth bonded return the transformer GTO/HT leads are at the

centre of the number of sections bridging is linked from the inside to out

on both sides at the ends the neon can be connected to the metal substrate

then a bonding cable from the substrate to the earth link of the transformer

it is required to label all of the return connections with the correct warning

labels this method is normally kept to large sky signs that need lifting

equipment to access

Long loop transformer GTO/HT leads are at the end of the

number of sections bridging is linked from section to

complete the loop, an earth return will seperate both sides

of the transformer but it is also inefficient way for loading

a transformer if a metal substrate is used the metal must be

earthed to the transformer

Long loop transformer GTO/HT leads are at the end of the

number of sections bridging is linked from each section to

complete the loop. Below’s wiring scheme is basically the

easiest to use, but it is the most inefficient way for loading

a transformer. if a metal substrate is used the metal must be

earthed to the transformer

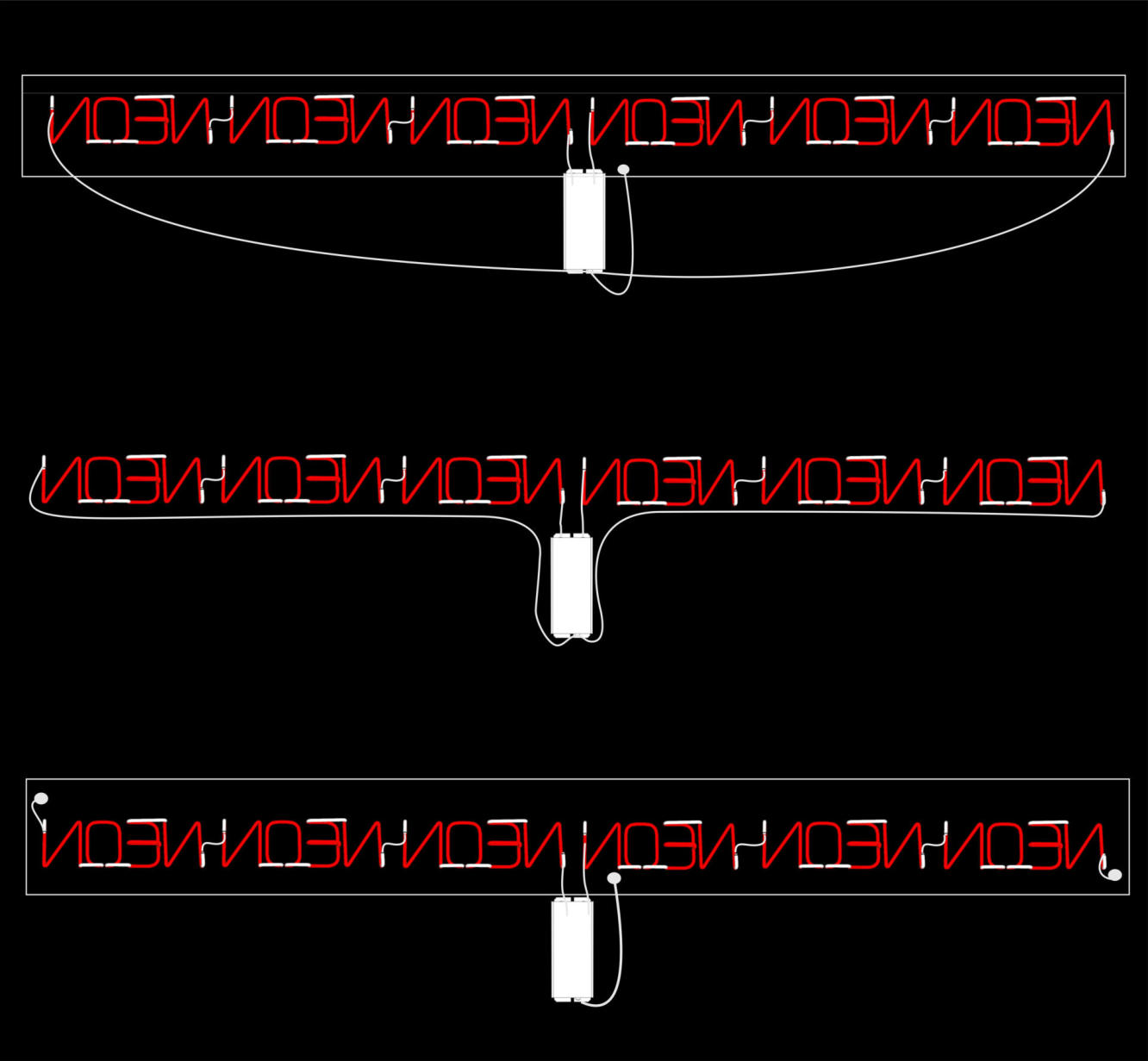

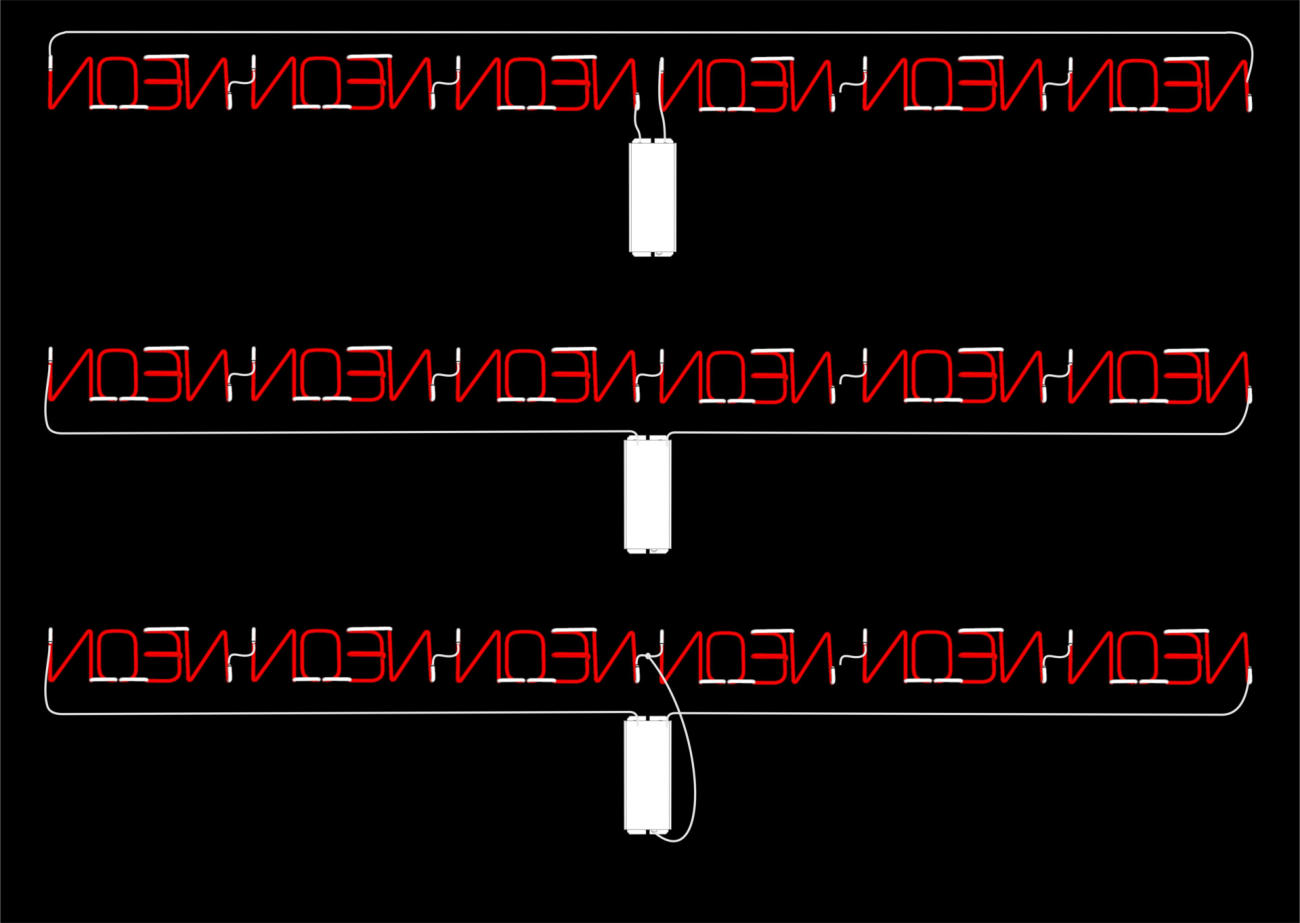

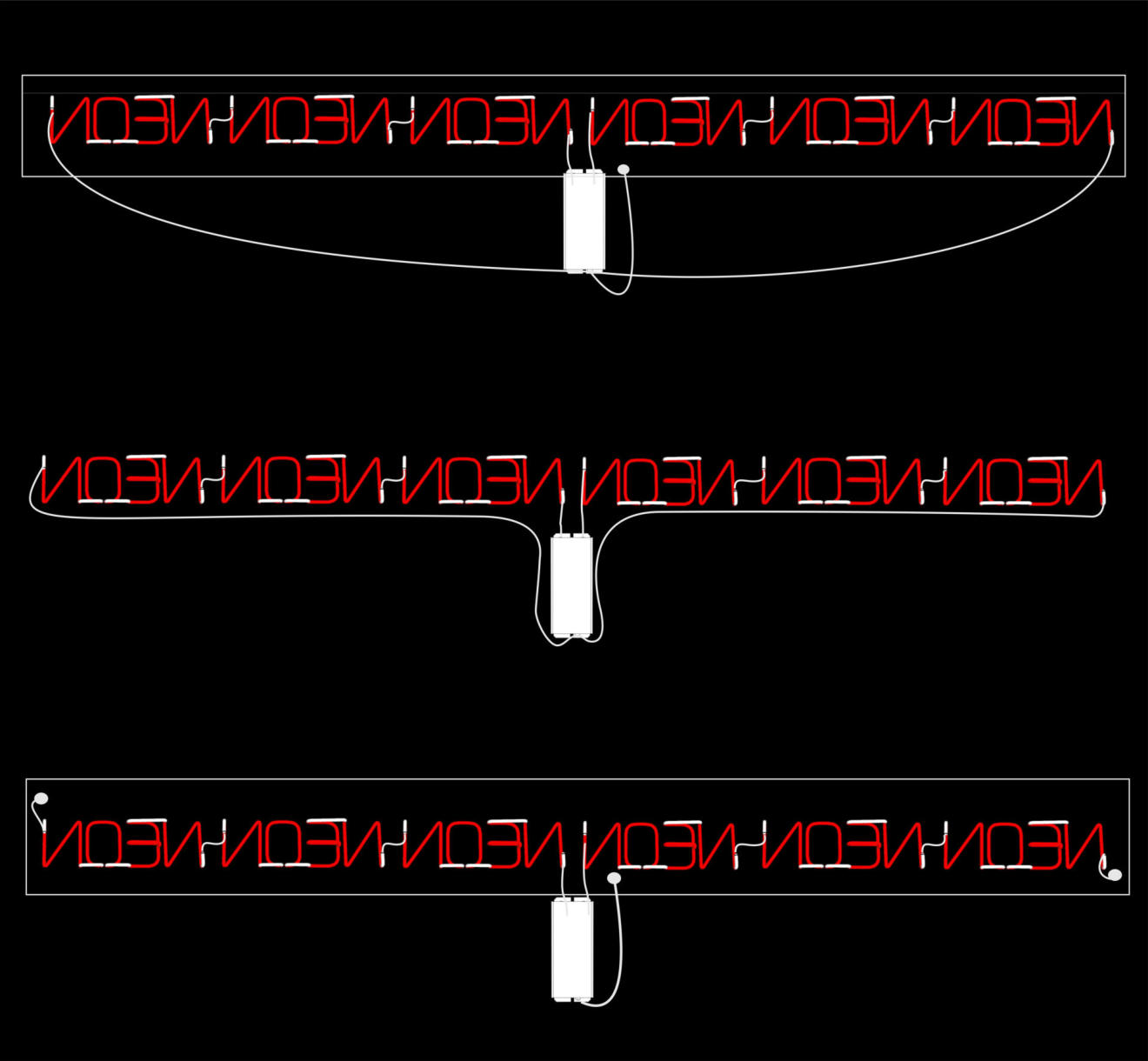

Centre Tap loop

Long loop

Earth Return loop

Centre tap loop transformer GTO/HT leads are at the

centre of the number of sections bridging is linked from

the inside to out on both sides at the ends a long link is

used to complete the loop if a metal substrate is used the

metal must be earthed to the transformer

Centre tap earth return the transformer GTO/HT leads are at

the centre of the number of sections bridging is linked from

the inside to out on both sides at the ends a long bridge is

used to complete the circuit by connecting both to the earth

point of the transformer it is required to label all of the

metal surface connections with the correct warning labels.

This method can also be used to wire to seperate signs as

long as the footage is rated to each side of the transformer.

Centre tap Earth return the transformer GTO/HT leads are

at the centre of the number of sections bridging is linked

from the inside to out on both sides at the ends the neon

are connected to the earth point of the transformer, when

on a metal surface there must also be an earth link from

the transformer to the metal surface it is required to label

all of the return connections with the correct warning labels

Centre tap earthed return

Centre tap earth return

Centre tap earthed bonded

Centre tap earth bonded return the transformer GTO/HT

leads are at the centre of the number of sections bridging

is linked from the inside to out on both sides at the ends

the neon can be connected to the metal substrate then a

bonding cable from the substrate to the earth link of the

transformer it is required to label all of the return connections

with the correct warning labels this method is normally

kept to large sky signs that need lifting equipment to access

Long loop transformer GTO/HT leads are at the end of the

number of sections bridging is linked from section to

complete the loop, an earth return will seperate both sides

of the transformer but it is also inefficient way for loading

a transformer if a metal substrate is used the metal must be

earthed to the transformer

Long loop transformer GTO/HT leads are at the end of the

number of sections bridging is linked from each section to

complete the loop. Below’s wiring scheme is basically the

easiest to use, but it is the most inefficient way for loading

a transformer. if a metal substrate is used the metal must be

earthed to the transformer